Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

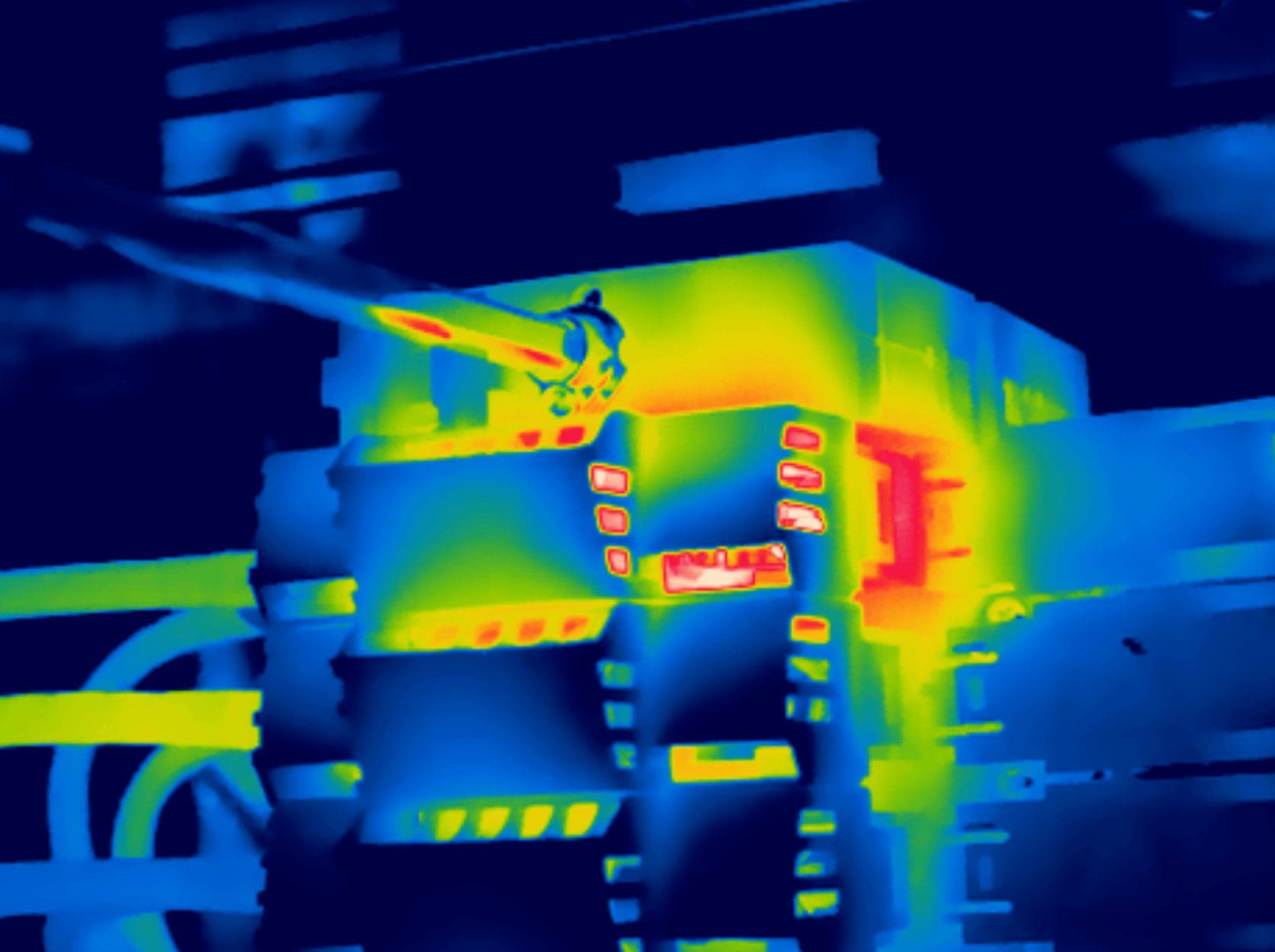

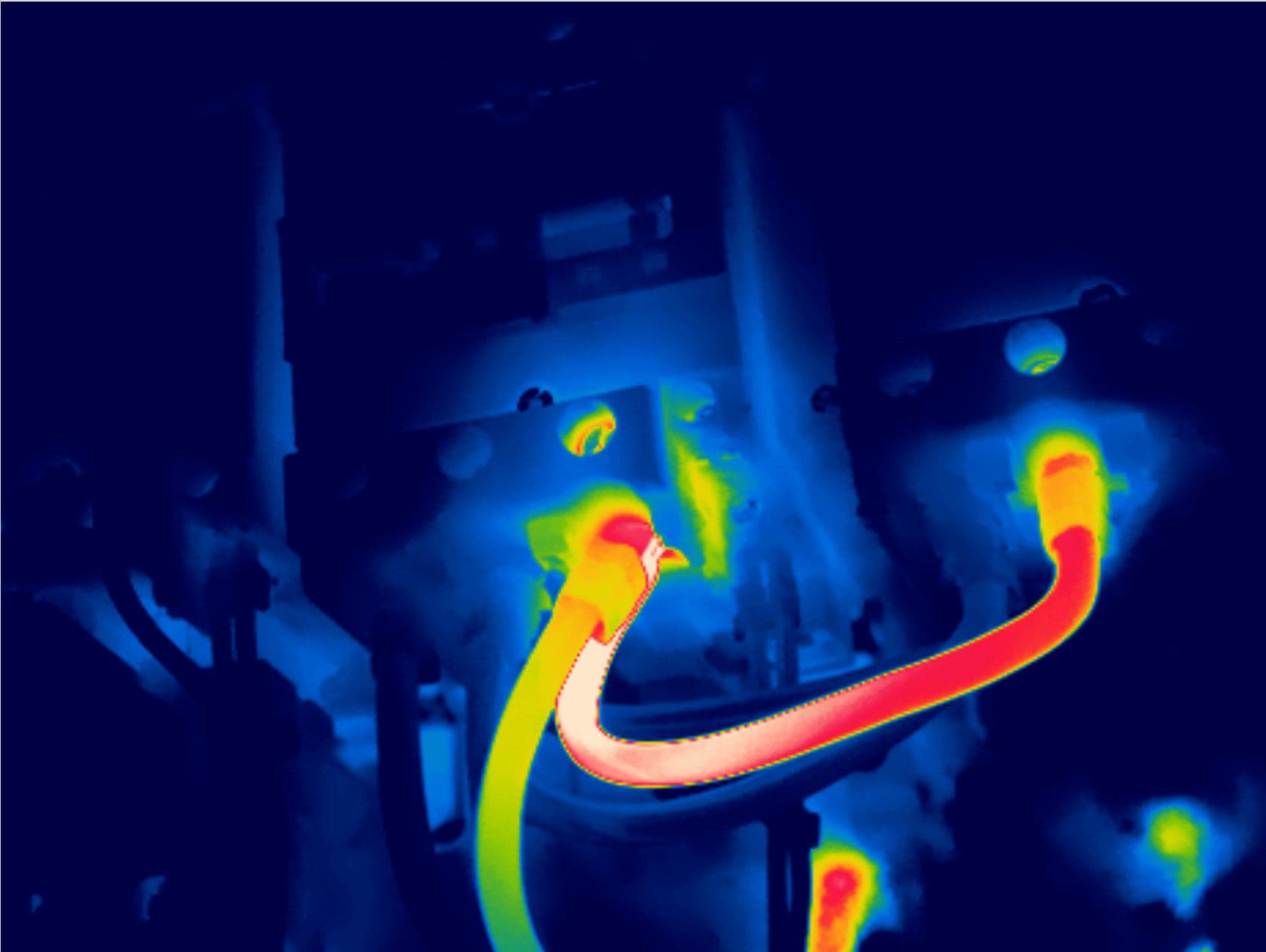

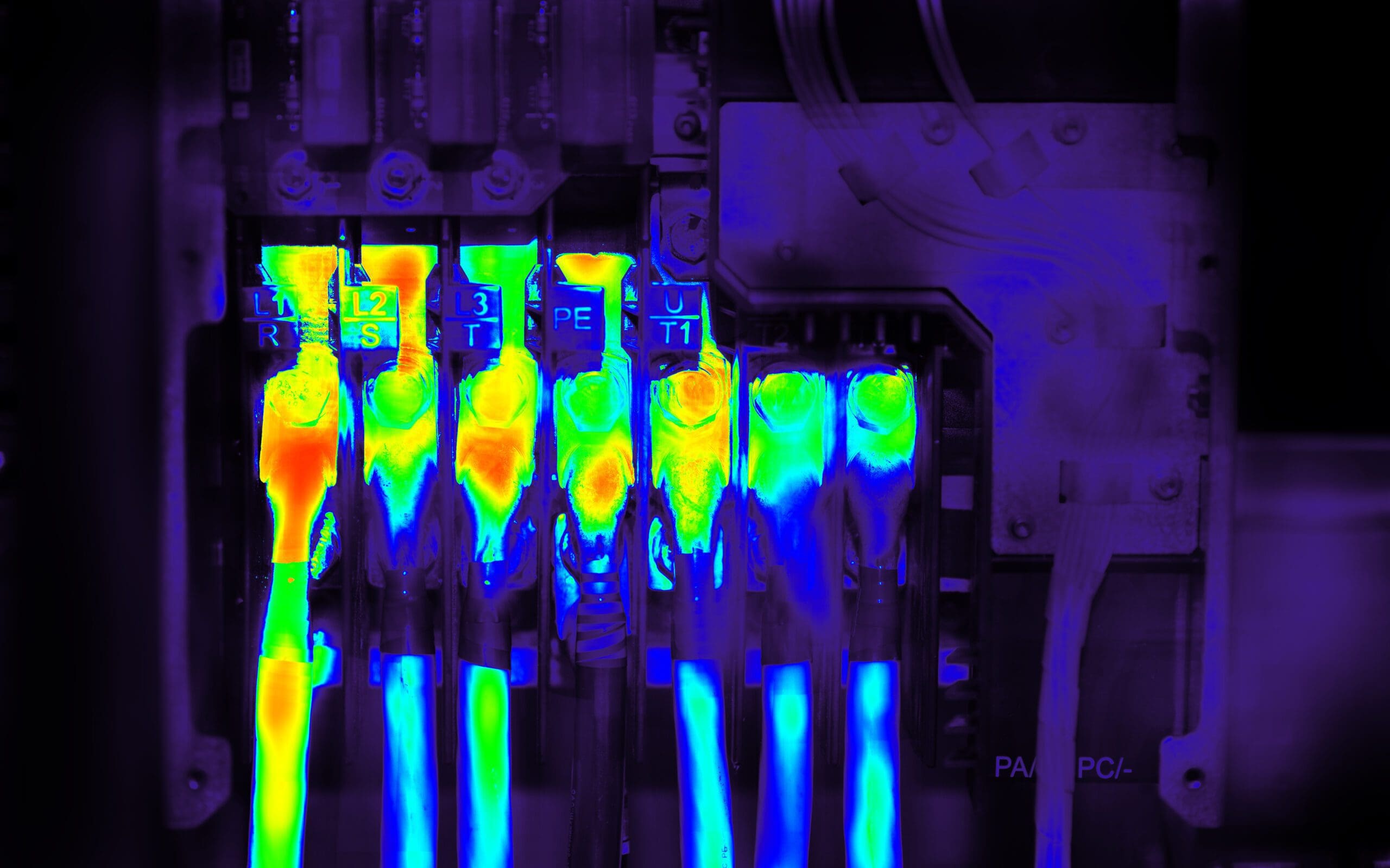

Thermal Imaging Surveys

Keeping your critical systems fault-free

Hidden threats lurk beneath the surface of your electrical system. Faulty connections, overloaded circuits, and potential hazards hide in plain sight, waiting to disrupt your operations and compromise safety.

Thermal Imaging Surveys act as your infrared vision, revealing these issues before they erupt into costly problems and cause downtime for your operations.

Comprehensive Thermal Imaging Surveys

If you’re concerned about having to down tools for the testing process, don’t be. Our thermal imaging service accommodates for peak operational hours, as we use specialist, non-intrusive equipment.

The Electricity at Work Regulations Act 1989, Health & Safety at Work Act 1974 and BS 7671 (IEE Wiring Regulations 18th Edition as amended) suggest that electrical infrastructure be regularly maintained and tested to ensure compliance with safety guidelines, and that’s where we come in.

We’ll work with you and your site requirements when carrying out our thermal imaging surveys to provide you with a comprehensive diagnosis and solution of underlying issues within your plant and equipment.

During a thermal imaging survey of your electrical equipment, our team at BES Group follows a precise process to uncover hidden issues and ensure the safety and efficiency of your systems.

Our Thermal Imagine process

Pre-survey planning

- Consultation and scope setting: We discuss your equipment, concerns, and desired outcomes to tailor the survey accordingly.

- Equipment selection: We choose the appropriate thermal imaging camera based on your specific needs and the type of equipment being inspected.

- Scheduling and site preparation: We coordinate the survey time to minimise disruption and advise on any needed preparations like removing obstructions or turning off lights.

Survey execution

- Data collection: Our qualified engineers use the thermal imaging camera to scan electrical panels, boards, switches, connections, and other components.

- Temperature analysis: The camera converts infrared radiation into visual images, highlighting areas with abnormal heat signatures.

- Load correction factor: We utilise a unique formula that considers equipment load and ambient temperature, allowing for accurate assessment of permitted heat limits for each component.

- Real-time discussion and explanation: Our team discusses any anomalies observed with you, explaining their potential implications and next steps.

Analysis and reporting

- Image and data interpretation: Our technical team thoroughly analyses the thermal images and collected data, identifying potential hazards, areas of heat loss, and other key findings.

- Report generation: We create a comprehensive report detailing the survey results, including thermal images, measurements, identified anomalies, and recommendations for corrective actions.

- Discussion and action plan: We discuss the report findings with you in detail, ensuring a clear understanding of the issues and formulating a plan for addressing them.

Schedule a call to find out how our thermal imagine surveys can benefit your organisation

Get in touch today Get in touch today Get in touch todayDid you know...

25%

reduction in heat loss could be achieved with thermal imaging surveys, as found by the Carbon Trust.

£200,000

was saved by a UK power plant when thermal imaging discovered an issue with a heat exchanger, as found by the Fraunhofer Institute for Manufacturing Engineering and Automation.

How Thermal Imagine can help you and your business

Early detection of potential hazards

Thermal imaging can be used to detect potential hazards, such as electrical fires, gas leaks, and structural defects, helping to prevent accidents and save lives.

Improved energy efficiency

Thermal imaging can be used to identify areas of heat loss, leading to energy savings and a reduction in costs!

Increased productivity

Thermal imaging can be used to identify and fix inefficiencies in industrial processes, boosting productivity and reducing costs.

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!

FAQs

Why undertake a thermal imaging survey?

+

Thermal imaging is best carried out when the electrical system is functioning under normal conditions, which negates the need of operational downtime. Problems are spotted before they become larger issues, helping to increase the lifespan of your system or equipment.

Will this service disrupt the running of my business?

+

No. In fact, the more pressure on your electrical machinery the better. We are able to see how your system operates when operating at full load capacity, providing a more accurate reading.